Why the Mining Industry Needs GEM

The Mining Industry Can’t Afford Mistakes

It’s not just one-off accidents anymore. Explosives-related incidents are being reported with disturbing regularity across WA, QLD and NSW. Misfires. Missing product. Inadequate reconciliation. If you’re still relying on paper-based systems or delayed digital inputs, you’re not just out of date, you’re exposed.

GEM was built specifically to prevent the exact failures regulators are reporting.

This Is Bigger Than Minesites. It’s a Public Safety Issue.

Explosives don’t stay on site. In recent years, we’ve seen counter-terrorism investigations linked to missing or illicit explosive materials.

The risk is no longer theoretical. It's real. And traceability is no longer optional, it’s essential.

These Failures Aren’t Hypothetical. They’re Happening Now.

Here’s what the industry is dealing with.

Recent Explosives Incidents in Australia:

WA: Boosters and detonators left in underground equipment, discovered later on surface, after hot works were carried out nearby.

WA: Incorrect box/pallet deliveries with poor reconciliation, resulting in a reportable situation under the Dangerous Goods Safety Act.

QLD: Explosives washed into drains during rain - wet-weather controls failed, exposing another layer of risk.

NSW: Dozer initiated a blast from a months-old misfire. Not great.

NSW: Ongoing alerts around unidentified misfires during excavation.

➔ All of these point to the same issue: gaps in live reconciliation, traceability, environmental controls and misfire clearance.

And they’re the exact gaps GEM closes.

What GEM Does That Manual Systems Can’t

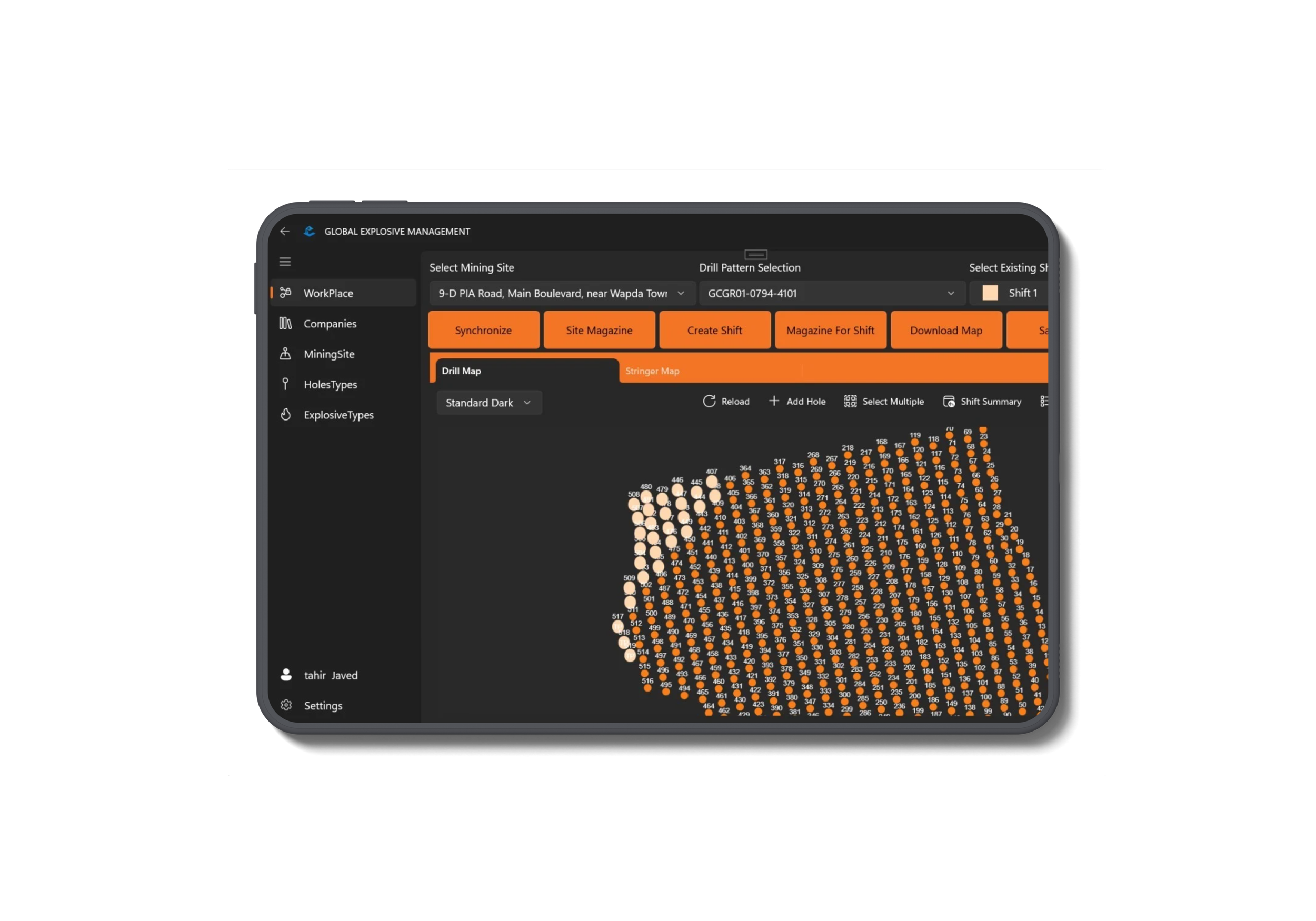

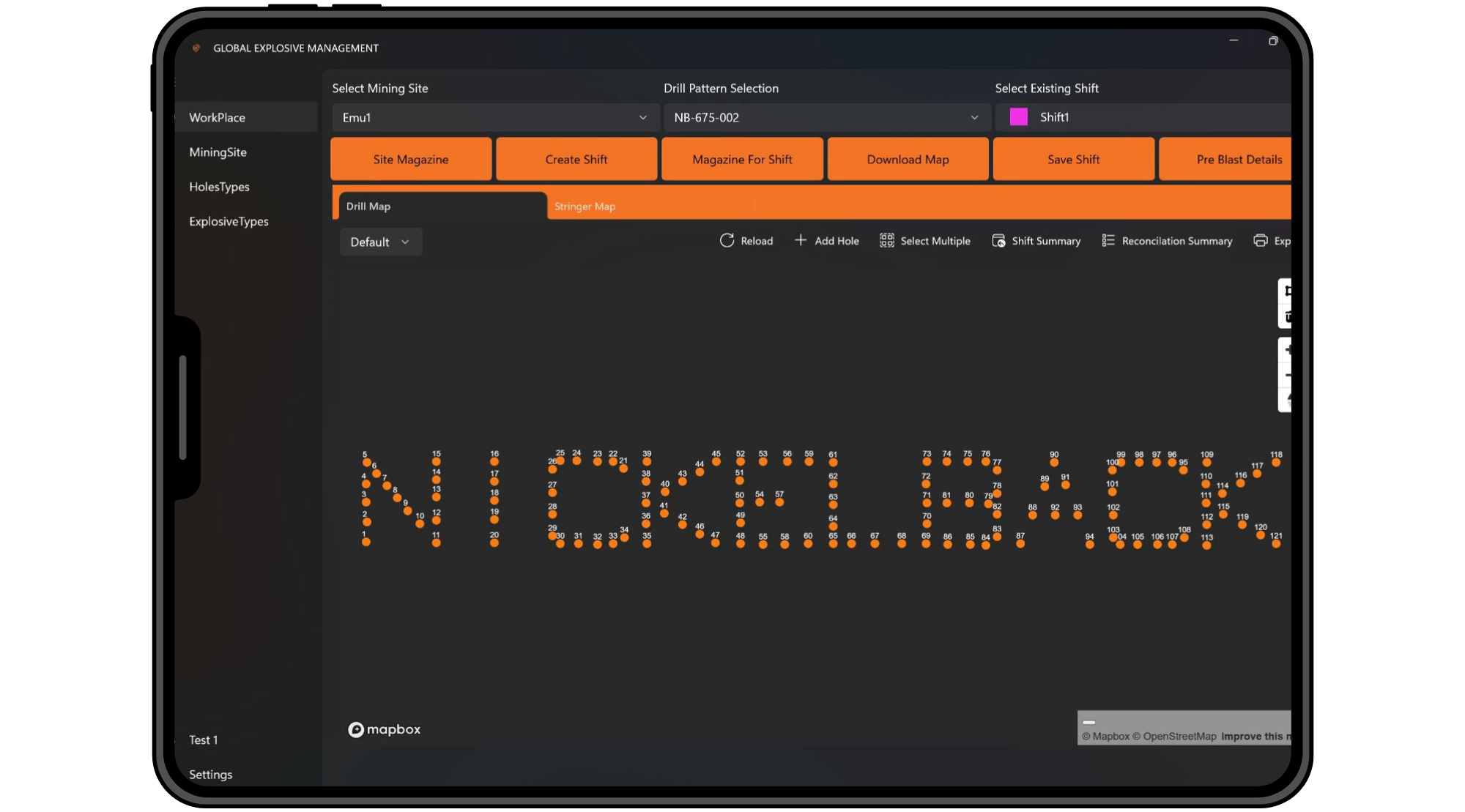

Live Reconciliation

No more end-of-shift balancing. GEM flags issues before you move a product or piece of plant.

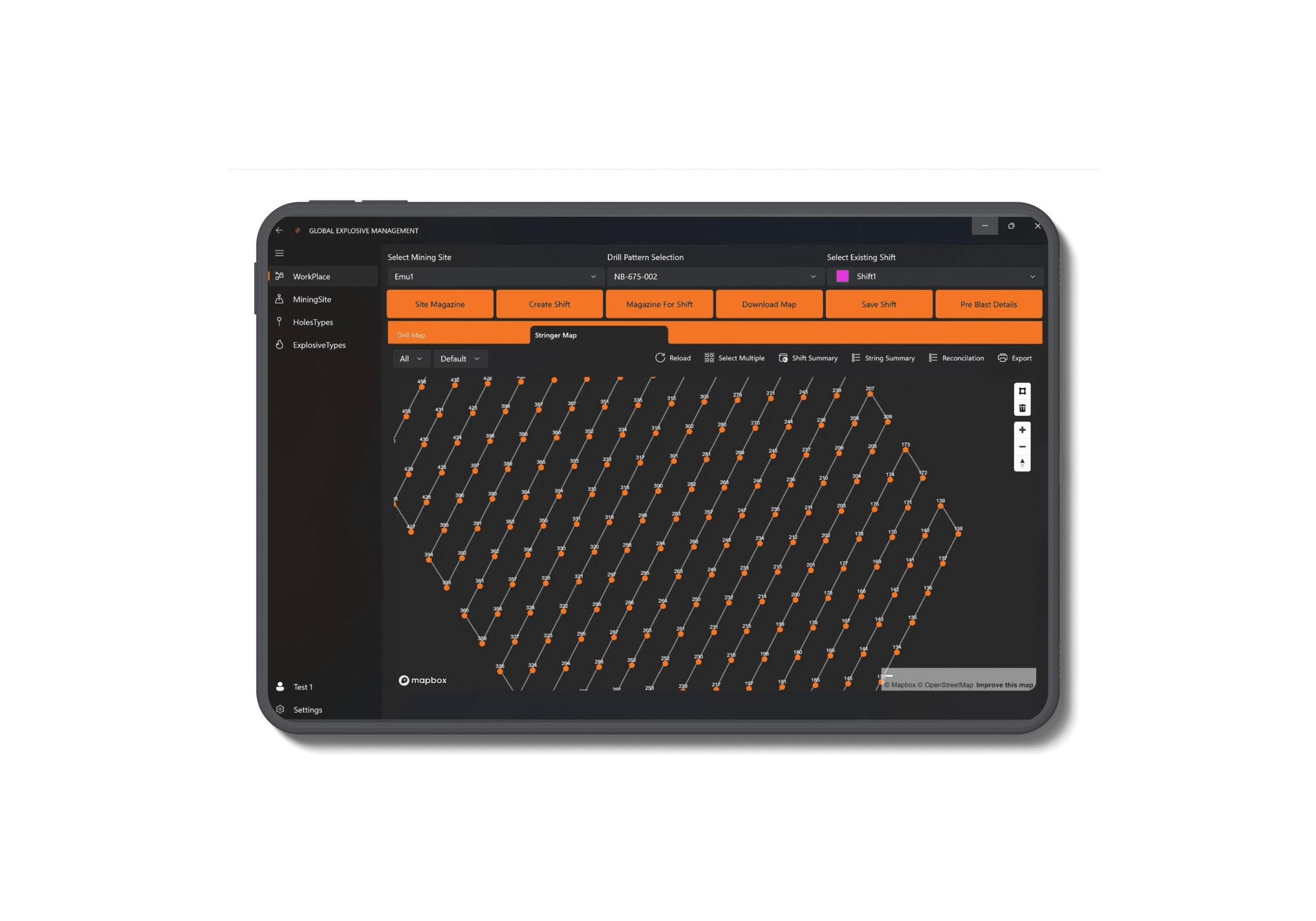

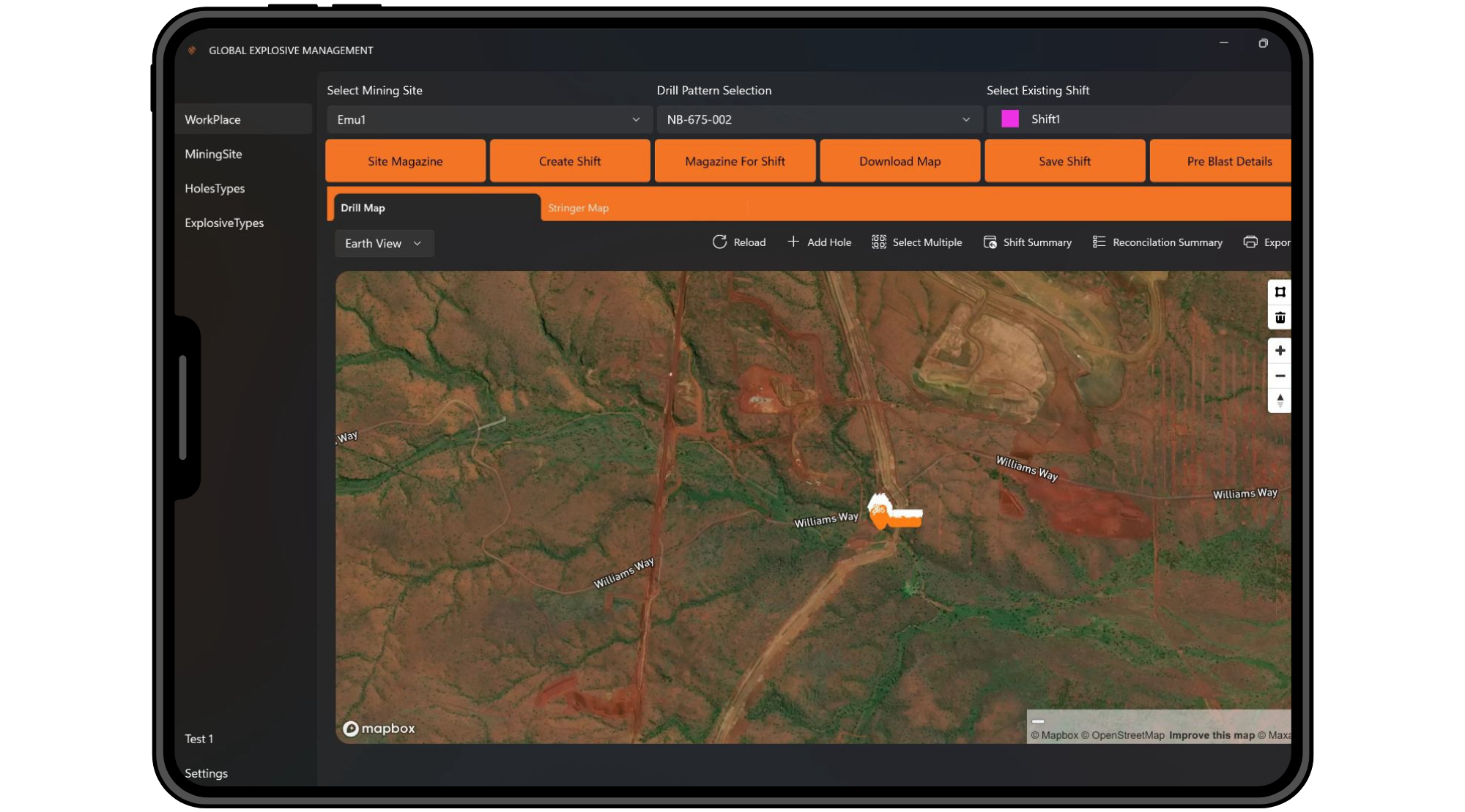

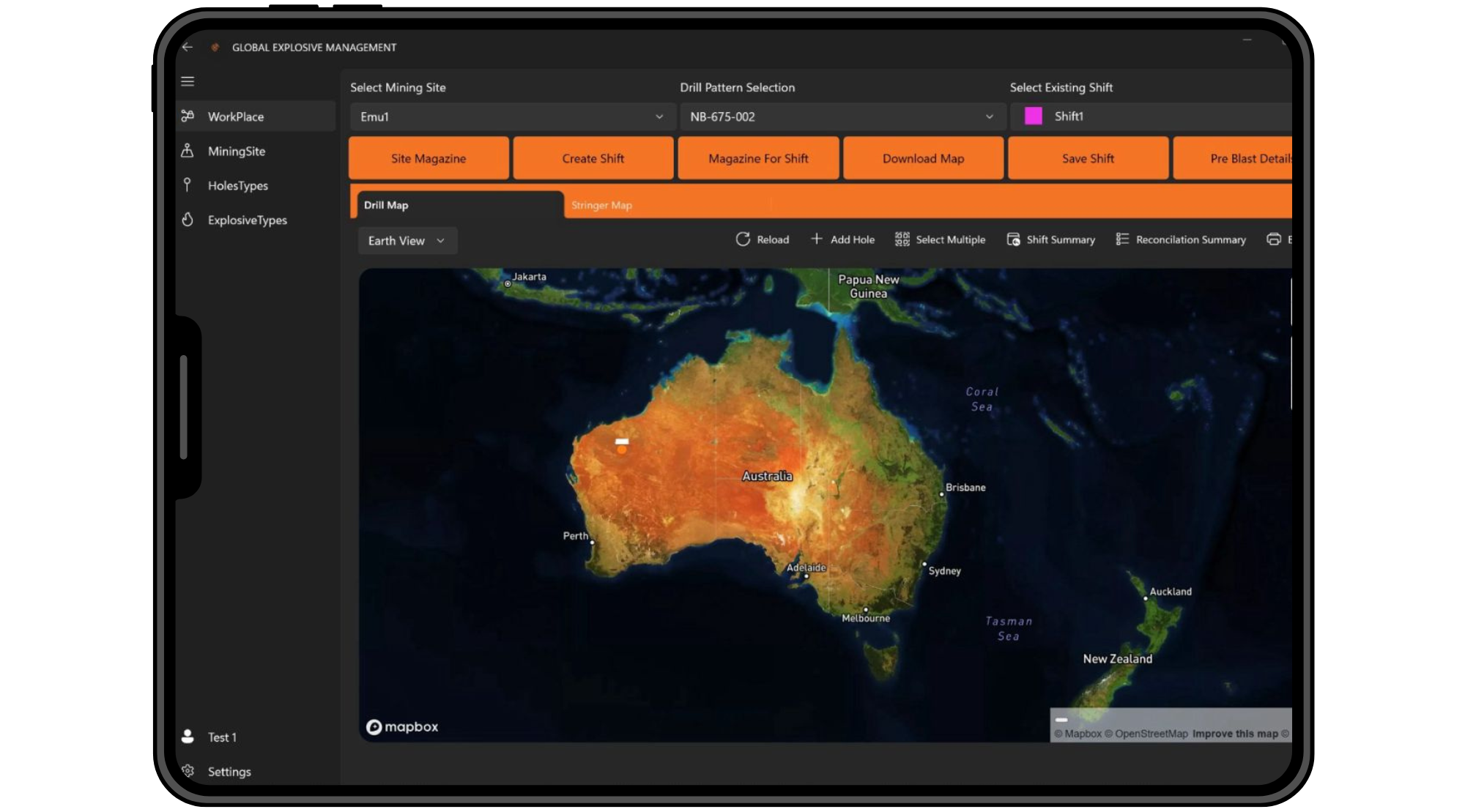

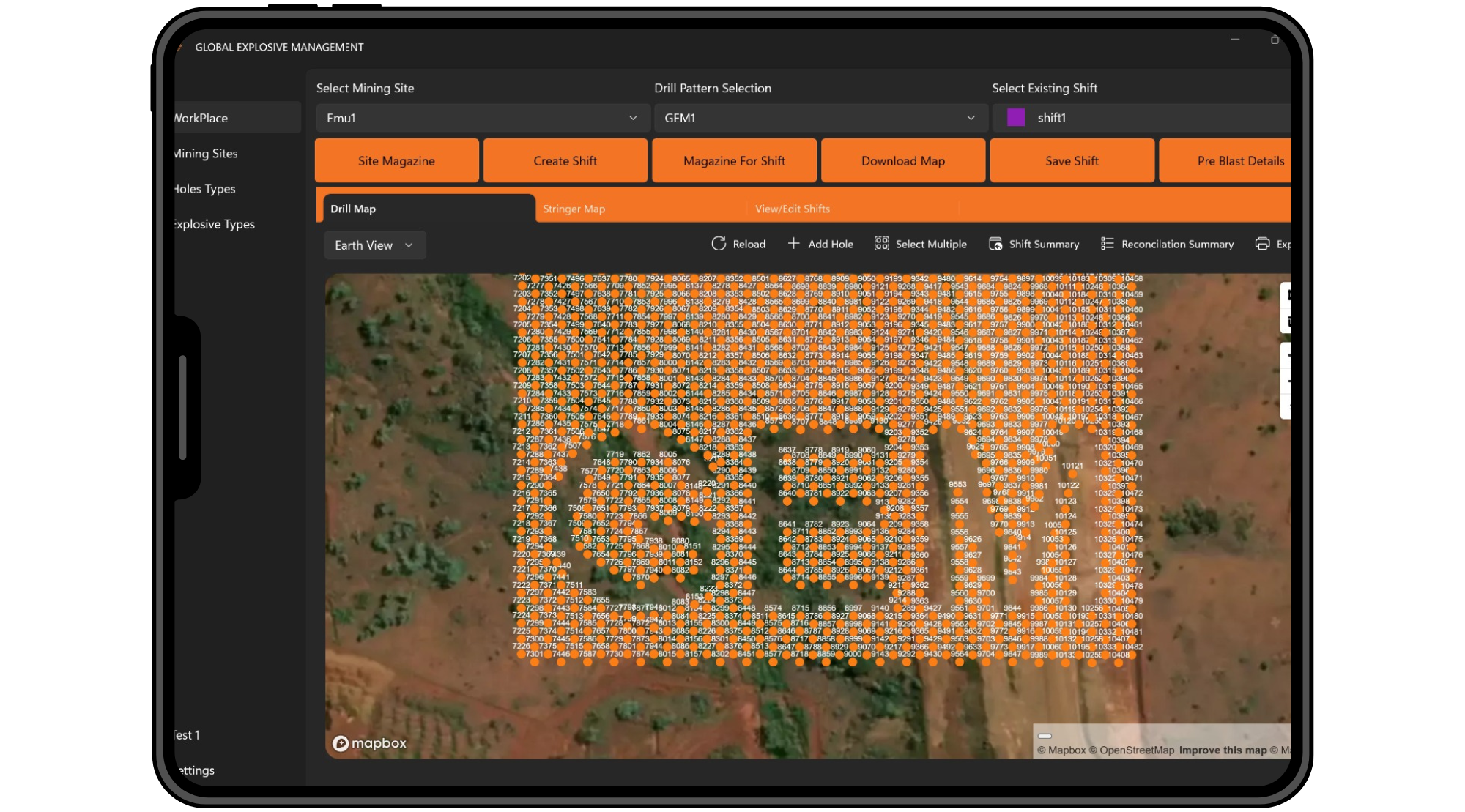

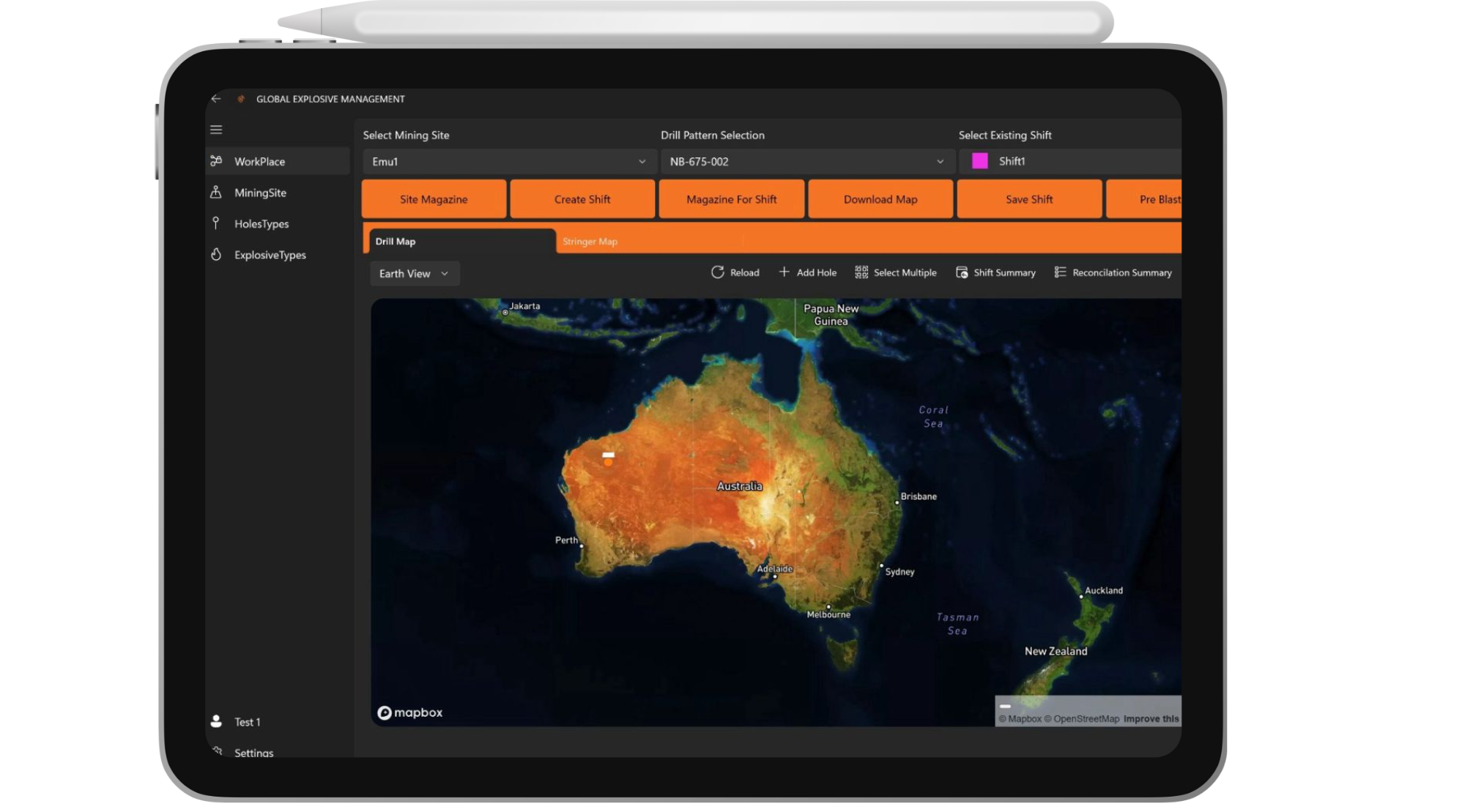

Delivery-to-Hole Traceability

Track every item from delivery through to detonation and have the data to prove it.

Weather + Event Flags

Rain? Delay? No problem. GEM captures environmental context in real-time so nothing slips through.

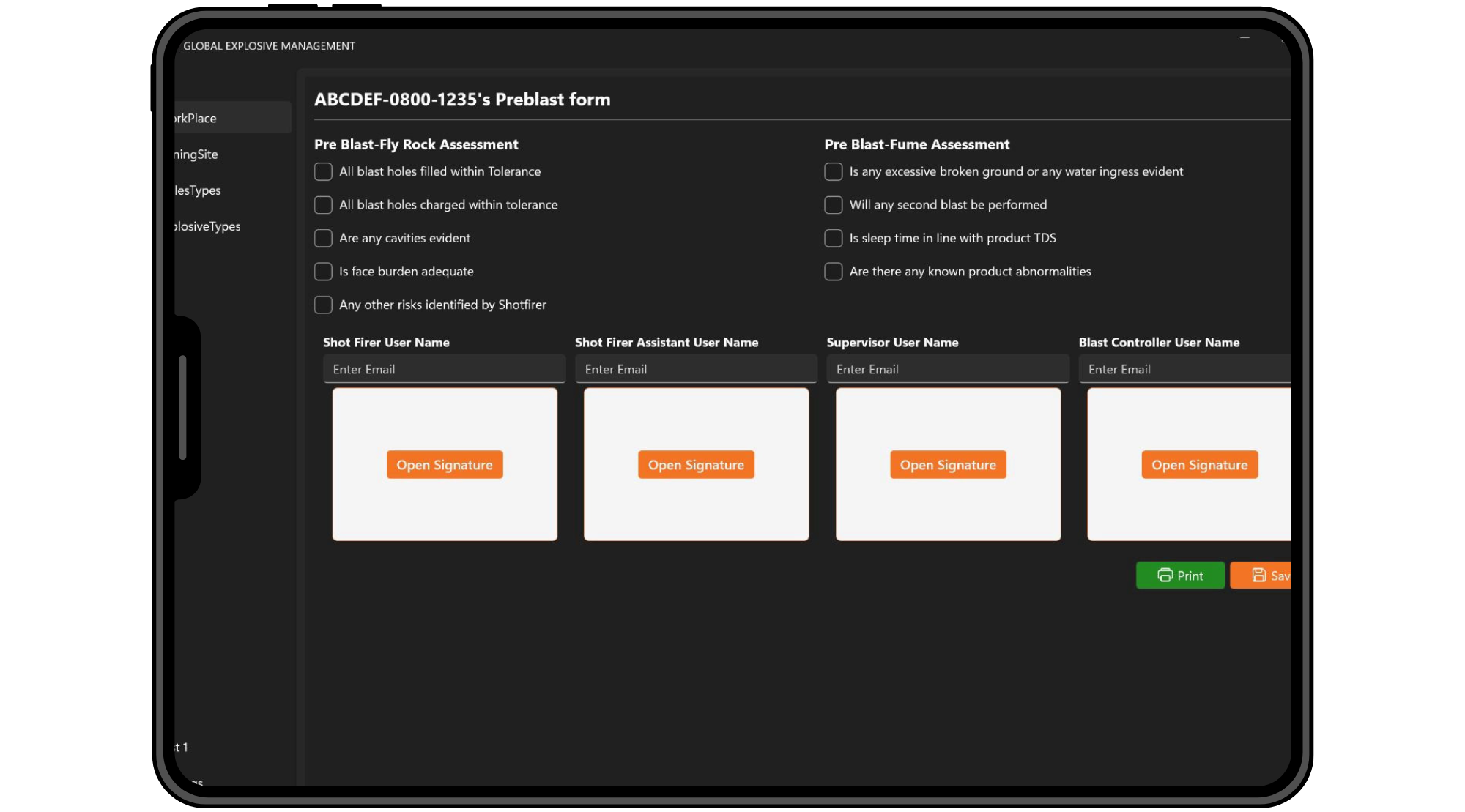

Misfire Clearance Verification

Never wonder again whether misfired product was fully accounted for. GEM gives you audit-ready confidence.

Regulators Aren’t Just Watching: They’re Signalling Change

Regulatory authorities across the country are tightening their expectations. And they’re not being subtle about it.

WA

Bulletins highlight reconciliation failures, unaccounted items and even theft investigations.

Referencing: Dangerous Goods Safety (Explosives) Regulations 2007, AEC3, AS 2187.

QLD

RSHQ now expects full incident reporting, every time.

Wet-weather events are under scrutiny.

NSW

Weekly incident reports show just how common accountability failures still are.

Translation? GEM aligns directly with these rising compliance expectations, and makes audits faster, cleaner and easier to pass.

Want to avoid your mine’s name showing up in the next safety bulletin?

Let’s talk about how GEM can lock your controls tight.